Beijing Funate Innovation Technology Co., Ltd. (Beijing, CN) and Hon Hai Precision Industry Co., Ltd. (Tu-Cheng, Taipei Hsien, TW) garnered U.S. Patent 7,638,933 for their electron emission device made with yarn woven from carbon nanotubes.

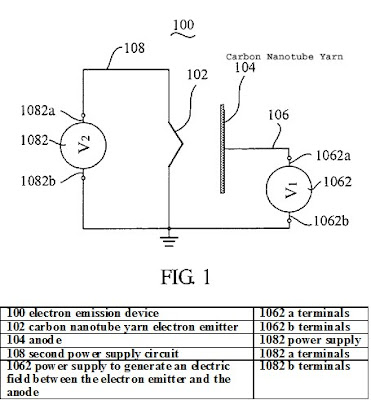

The electron emitter is comprised of one-dimensional nanostructures made with carbon nanotubes; an anode opposite to and spaced apart from the electron emitter. A first power supply circuit configured for electrically connecting the electron emitter and the anode with a power supply to generate an electric field between the electron emitter and the anode; and a second power supply circuit configured for electrically connecting the electron emitter with a power supply to supply a heating current for heating the electron emitter causing it to emit electrons.

The electron emitter further comprises a sleeve defining an opening therein and a filament placed in the opening, and the one-dimensional nanostructures are formed on an outside surface of the sleeve and electrically connected therewith, the first power supply circuit is electrically connected with the anode and the sleeve, and the second power supply circuit is electrically connected with two terminals of the filament.

FIG. 1 is a schematic view of an electron emission device incorporating a carbon nanotube yarn acting as the electron emitter.

FIG. 2 is a transmission electron microscope (TEM) image of the carbon nanotube yarn of FIG. 1, (scale bar is 20 micrometers). The carbon nanotube yarn is usually composed of a plurality of carbon nanotubes parallel to one another and bundled together by van der waals interactions.

The carbon nanotube yarn usually has a diameter of no less than 1 micrometer. In the illustrated embodiment, the carbon nanotube yarn is bended and has a diameter of about 20 micrometers and a length of about 2 centimeters. A method for fabricating the carbon nanotube yarn can include the steps of forming a initial carbon nanotube yarn by way of pulling out a bundle of carbon nanotubes from a super-aligned carbon nanotube array.

The second power supply circuit is used to supply a heating voltage/current to heat the electron emitter to emit electrons, whereby an emission current is achieved. Because the heating voltage is relatively lower, preferably ranging from about 15 to 100 volts, and the emission current is related to the heating voltage, accordingly the emission current can be readily adjusted by way of varying the magnitude of the heating voltage. Furthermore, molecules accumulated at the electron emitter can be substantially removed via the heating voltage/current; consequently, the electron emission device can achieve an emission current with a relatively higher stability, even though the electron emitter is operated at relatively low vacuum.

The heating voltage is in the range from about 15 to 100 volts, which can heat the electron emitter up to a temperature ranging from about 1500 to 2000 kelvins (K) correspondingly. Generally, the heating voltage is related to the length of the carbon nanotube yarn (i.e. the electron emitter), the shorter of the length of the carbon nanotube yarn, the lower of the heating voltage required.

Typical electron emission devices incorporating carbon nanotubes each includes a cathode with carbon nanotubes acting as electron emitter formed thereon, and a counter anode with a phosphor layer formed thereon. Emission current can be obtained by applying a voltage difference of a few hundred volts to a thousand volts between the cathode and the counter anode which are received in a vacuum space. The strength of an emission current can be varied with the variation of the magnitude of the voltage difference.

The second power supply circuit is used to supply a heating voltage/current to heat the electron emitter to emit electrons, whereby an emission current is achieved. Because the heating voltage is relatively lower, preferably ranging from about 15 to 100 volts, and the emission current is related to the heating voltage, accordingly the emission current can be readily adjusted by way of varying the magnitude of the heating voltage. Furthermore, molecules accumulated at the electron emitter can be substantially removed via the heating voltage/current; consequently, the electron emission device can achieve an emission current with a relatively higher stability, even though the electron emitter is operated at relatively low vacuum.

The heating voltage is in the range from about 15 to 100 volts, which can heat the electron emitter up to a temperature ranging from about 1500 to 2000 kelvins (K) correspondingly. Generally, the heating voltage is related to the length of the carbon nanotube yarn (i.e. the electron emitter), the shorter of the length of the carbon nanotube yarn, the lower of the heating voltage required.

Typical electron emission devices incorporating carbon nanotubes each includes a cathode with carbon nanotubes acting as electron emitter formed thereon, and a counter anode with a phosphor layer formed thereon. Emission current can be obtained by applying a voltage difference of a few hundred volts to a thousand volts between the cathode and the counter anode which are received in a vacuum space. The strength of an emission current can be varied with the variation of the magnitude of the voltage difference.

Hon Hai Precision is more commonly known by its trade name, Foxconn and is one of the world's largest contract electronics manufacturers.